What is a Disc Dryer?

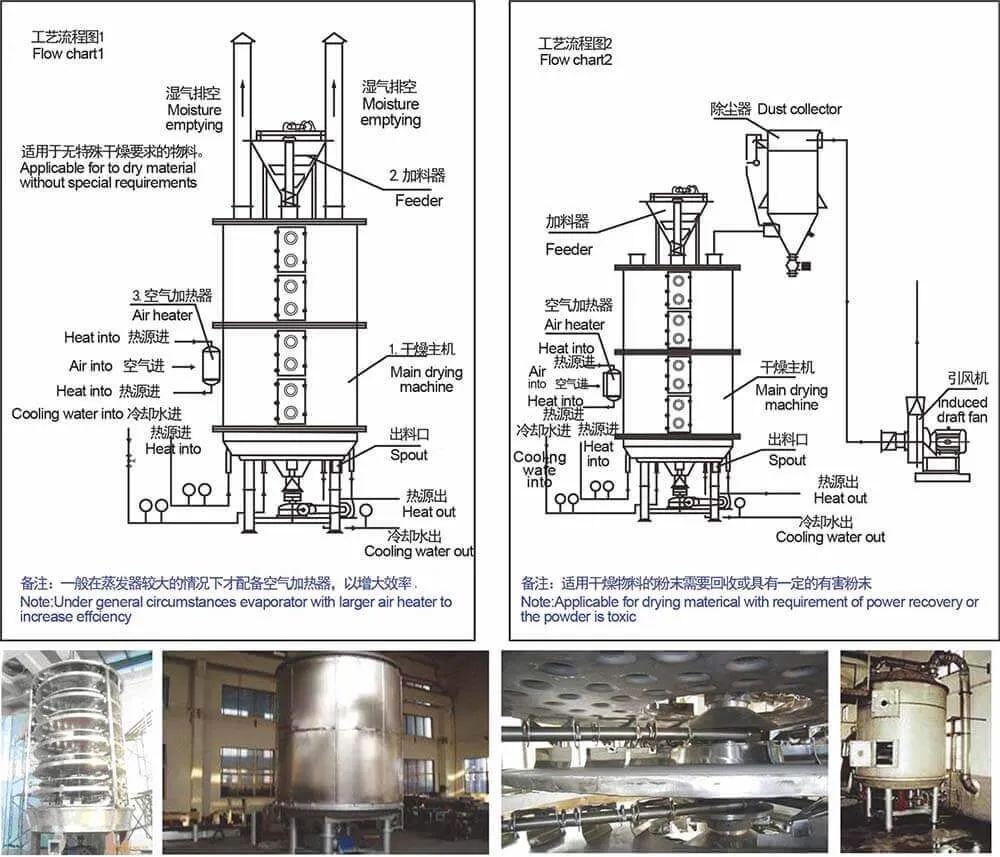

A disc dryer is an indirect-heating drying machine that uses a series of hollow, heated discs mounted on a rotating shaft inside a cylindrical shell. Steam, thermal oil, or hot water flows through the discs, transferring heat to the wet material through conduction.

As the shaft rotates, the heated discs agitate and lift the material, ensuring uniform mixing and continuous renewal of the heat transfer surface. This process allows efficient evaporation of moisture without direct contact between the material and hot air.

Disc dryers are widely used in the chemical, environmental, food, and wastewater treatment industries, especially for drying slurries, pastes, and sticky materials. They are valued for their high heat efficiency, compact design, and ability to handle difficult-to-dry materials.

- The reversal effects of the rake leaves, the dry and wet material to facilitate effective mixing, heat and mass transfersmoothly, improve drying rate.

- Drying process without dead zone, uniform drying, high drying quality, low energy consumption.

- The drying speed is fast, simple and convenient operation, strong applicability.

- Clean operation environment, Recyclable solvent, dust emissions to meet the requirements.

- Convenient installation.small occupation area.

Your Professional Disc DryerManufacturer in China

When it comes to reliable, high-performance drying systems, Bosiway stands out as your ideal partner. Here are four key reasons why you should choose us as your vacuum harrow dryer Manufacturer:

- Industry-Leading Expertise

With over 20 years of experience, Bosiway delivers customized Dryers designed for efficiency and reliability across diverse industries.

- Cutting-Edge Technology & Innovation

Our patented designs and cutting-edge heat transfer systems ensure optimal performance, low energy consumption, and consistent product quality.

- Competitive Pricing with Global Standards

As a leading Chinese manufacturer, we provide high-quality Dryers at affordable prices while meeting global standards.

- Full After-Sales Support

Enjoy 24/7 technical support, training, and maintenance services to keep your system running smoothly for years.

Our Services Always Go Extra Mile

Committed to Your Success

At Bosiway, we believe in building lasting partnerships. Our commitment to excellence extends far beyond installation. With ongoing maintenance, custom solutions, and rapid response service, we ensure your systems are always running smoothly—no matter the challenge.

Full-Cycle Support, Anytime You Need It

At Bosiway, our services don’t stop at equipment delivery. We go the extra mile by providing comprehensive support, from custom system design to on-site training and 24/7 customer service. We’re with you every step of the way to ensure your system performs at its best.

Your Long-Term Success Is Our Priority

We understand that great service is about more than just the initial sale. At Bosiway, our dedicated team provides tailored solutions, timely support, and proactive maintenance to guarantee your Paddle Dryer stays in peak condition, maximizing productivity and efficiency for years to come.

FAQs

A disc dryer is an indirect-heating drying machine equipped with multiple hollow discs mounted on a rotating shaft. Heat is supplied through the discs and the dryer shell, while the rotating action agitates the material to ensure uniform drying and high thermal efficiency.

Disc dryers are especially effective for slurries, pastes, sticky materials, and products with high moisture content. They are widely used in chemical, food, environmental, and wastewater treatment industries.

Large heat transfer area in a compact design

High drying efficiency and energy savings

Effective for difficult-to-dry, viscous, or sticky products

Low environmental impact with closed-system operation

While both are indirect-contact dryers, disc dryers are optimized for high-moisture, viscous materials due to their large heated surface area. Paddle dryers, by contrast, are more versatile and better suited for powders, granules, and heat-sensitive products.

Yes. Bosiway offers complete lifecycle support, including installation guidance, operator training, spare parts supply, and long-term maintenance services to ensure reliable operation and maximum equipment life.