What is Multiple Effect Evaporator?

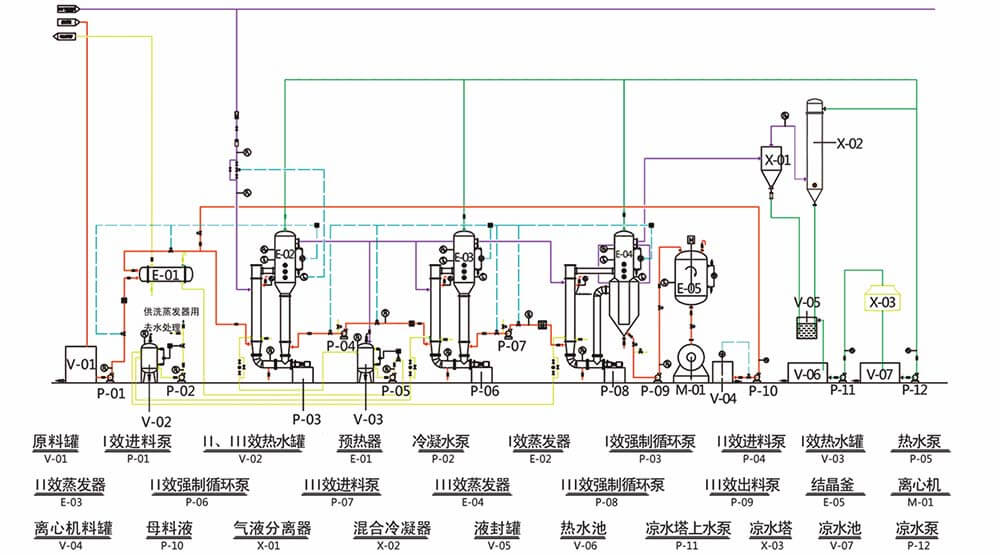

A Multiple Effect Evaporator (MEE) is an advanced industrial system designed to concentrate solutions—typically by removing water or other solvents—through the process of evaporation.

The key feature of an MEE is energy efficiency. Instead of using fresh steam in every stage, the vapor generated in one effect is reused as the heating medium in the next effect. This “cascading” use of vapor allows the system to perform the same evaporation task with much less steam and energy compared to a single-effect evaporator.

Working Concept

In a single-effect evaporator, steam is used once to heat and evaporate the liquid.

In an MEE, the vapor generated in the first effect (stage) is reused as the heating medium for the next effect, and so on.

Each subsequent effect operates at a lower pressure and temperature, allowing continuous evaporation with minimal additional steam consumption.

Key Features & Benefits

-

Energy Savings: Uses the same steam multiple times, reducing overall steam requirement.

-

Cost-Effective: Lower operational costs compared to single-effect systems.

-

Scalable: Can be designed with 2–6 effects (sometimes more), depending on concentration needs and energy efficiency targets.

-

Applications: Widely used in industries such as food processing, pharmaceuticals, chemicals, pulp & paper, textiles, and wastewater treatment.

In short: An MEE is essentially a steam economy system that maximizes energy utilization while concentrating liquids.

Your Professional Multiple Effect Evaporator Manufacturer in China

When it comes to reliable, high-performance drying systems, Bosiway stands out as your ideal partner. Here are four key reasons why you should choose us as your Paddle Dryer Manufacturer:

- Industry-Leading Expertise

With over 20 years of experience, Bosiway delivers customized Paddle Dryers designed for efficiency and reliability across diverse industries.

- Cutting-Edge Technology & Innovation

Our patented designs and cutting-edge heat transfer systems ensure optimal performance, low energy consumption, and consistent product quality.

- Competitive Pricing with Global Standards

As a leading Chinese manufacturer, we provide high-quality Paddle Dryers at affordable prices while meeting global standards.

- Full After-Sales Support

Enjoy 24/7 technical support, training, and maintenance services to keep your system running smoothly for years.

Our Services Always Go Extra Mile

Committed to Your Success

At Bosiway, we believe in building lasting partnerships. Our commitment to excellence extends far beyond installation. With ongoing maintenance, custom solutions, and rapid response service, we ensure your systems are always running smoothly—no matter the challenge.

Full-Cycle Support, Anytime You Need It

At Bosiway, our services don’t stop at equipment delivery. We go the extra mile by providing comprehensive support, from custom system design to on-site training and 24/7 customer service. We’re with you every step of the way to ensure your system performs at its best.

Your Long-Term Success Is Our Priority

We understand that great service is about more than just the initial sale. At Bosiway, our dedicated team provides tailored solutions, timely support, and proactive maintenance to guarantee your Paddle Dryer stays in peak condition, maximizing productivity and efficiency for years to come.

Projects Running in the World

FAQs

Our Paddle Dryers are ideal for a wide range of industries, including chemical processing, food production, pharmaceuticals, wastewater treatment, biomass, and petrochemicals. We specialize in handling sludges, slurries, powders, pastes, and heat-sensitive materials.

A Paddle Dryer uses indirect heat transferred through hollow paddles and a jacketed vessel to dry materials. The rotating paddles continuously mix the product to ensure uniform drying and prevent clumping, making it energy-efficient and effective for various applications.

Yes! At Bosiway, we provide customized Paddle Dryers tailored to your process requirements. Whether it’s adjusting the capacity, heating medium, or design, our engineering team works closely with you to deliver the perfect solution for your business.

We offer comprehensive after-sales support, including installation, operator training, 24/7 technical assistance, spare parts supply, and preventive maintenance to ensure your equipment runs smoothly and efficiently for years.

Our Paddle Dryers are designed with high thermal efficiency, which significantly reduces energy consumption compared to traditional drying methods. The indirect heating system ensures that heat is efficiently transferred to the material, minimizing energy costs and enhancing overall performance.