What is a Fluid Bed Dryer?

A fluid bed dryer is an industrial drying system used to process granular materials, powders, and particulate solids. In this system, hot air is passed through a bed of wet material, causing the material to be suspended and agitated by the airflow. The hot air accelerates the evaporation of moisture, drying the material quickly and efficiently. This type of drying is popular in industries like pharmaceuticals, chemicals, food processing, and powder coating due to its uniform heat distribution and ability to handle heat-sensitive materials.

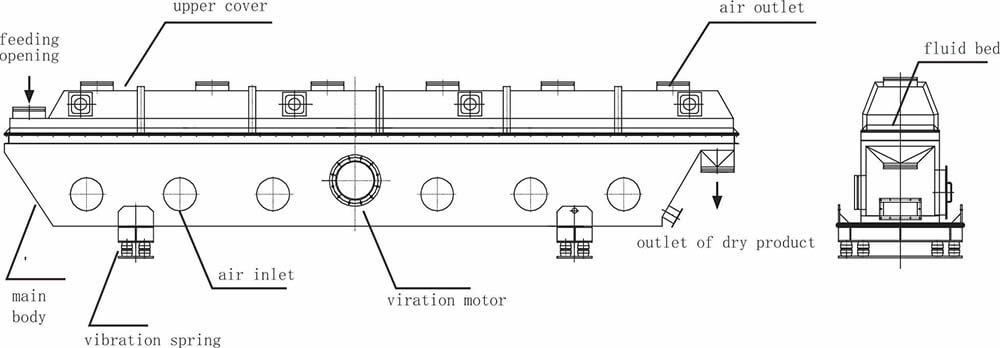

Material from the feeder into the dryer, under the action of the exciting force and bottom-up, hot air under thejoint action of fluidized bed,material along the horizontal direction will move forward continuously, the hot airpasses through the fluidized bed sieve plate heat and mass transfer process, to achieve the puroose of drvinacan be divided into two segments according to the drying production needs, the first half ofpart with hot air todry, the latter part of the material with high temperatureair cooling, packaging reguirements. Wet air through theprecipctator dust as the exhaust gas removal.dry material from the discharge port.

- Easily exchangeable distribution plate

- Very effective emptying when changing products

- Explosion-protected version

- High equipment availability

- Special sizes

- Heat recovery from the dryer exhaust air

- Multi-stage processes can be performed in a single step

- Dust removal by cyclone, exhaust filter or gas scrubber

- In the inert gas circuit and with solvent recovery

- With simple controls or completely automated via process control systems

1. Pharmaceutical chemical industry: a variety of hit film grain, boric acid, borax, various additives such ashydroquinone.

2. Food and building materials industry: lees, monosodium glutamate, sugar, salt, slag, watercress seeds and so on.

3. Adapted to the chemical, pharmaceutical, food, beverages, seeds, slag and other industries a variety of granularmaterials crystal, powder mixes drying, cooling, humidification operation

4. Other: powder, metal powder, grit, food, furfural, silica sand, toners, pots, glutamic acid, silica, abrasive materialsfertilizers, grass meal, bone meal and so on.

Your Professional Fluid Bed DryerManufacturer in China

When it comes to reliable, high-performance drying systems, Bosiway stands out as your ideal partner. Here are four key reasons why you should choose us as your fluid bed Manufacturer:

- Industry-Leading Expertise

With over 20 years of experience, Bosiway delivers customized Dryers designed for efficiency and reliability across diverse industries.

- Cutting-Edge Technology & Innovation

Our patented designs and cutting-edge heat transfer systems ensure optimal performance, low energy consumption, and consistent product quality.

- Competitive Pricing with Global Standards

As a leading Chinese manufacturer, we provide high-quality Dryers at affordable prices while meeting global standards.

- Full After-Sales Support

Enjoy 24/7 technical support, training, and maintenance services to keep your system running smoothly for years.

Our Services Always Go Extra Mile

Committed to Your Success

At Bosiway, we believe in building lasting partnerships. Our commitment to excellence extends far beyond installation. With ongoing maintenance, custom solutions, and rapid response service, we ensure your systems are always running smoothly—no matter the challenge.

Full-Cycle Support, Anytime You Need It

At Bosiway, our services don’t stop at equipment delivery. We go the extra mile by providing comprehensive support, from custom system design to on-site training and 24/7 customer service. We’re with you every step of the way to ensure your system performs at its best.

Your Long-Term Success Is Our Priority

We understand that great service is about more than just the initial sale. At Bosiway, our dedicated team provides tailored solutions, timely support, and proactive maintenance to guarantee your Paddle Dryer stays in peak condition, maximizing productivity and efficiency for years to come.

Projects Running in the World

FAQs

A fluid bed dryer uses a stream of hot air to fluidize solid particles, suspending them in motion. This process allows for fast, uniform heat transfer, ensuring that powders, granules, or pellets are dried evenly and efficiently.

Fluid bed dryers are suitable for a wide range of industries. They are commonly used for drying powders, granules, and pellets in pharmaceuticals, food processing, chemicals, animal feed, and agricultural products.

Rapid and uniform drying

Energy-efficient heat transfer

Gentle handling of heat-sensitive products

Flexible design for batch or continuous production

There are several types, including conventional, vibrated, spouted bed, and spray-assisted (top-spray or bottom-spray) fluid bed dryers. Each design is chosen based on the material properties and application requirements.

Yes. Bosiway offers full technical support, including installation guidance, operator training, spare parts supply, and long-term maintenance services to ensure optimal equipment performance.